MRP glossary TOP > Material Planning > Calculating Net Requirements

Calculating Net Requirements

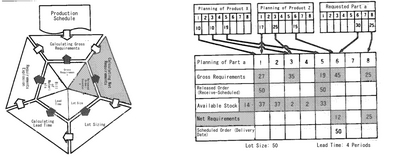

It functions as part of MRP's planning, and is calculated by allocating the total requirements based on the MRP list to inventory and released orders. The calculated requirements are taken over to the lot sizing process (the subsequent process) for logistics. Net requirements is obtained by means of the following procedure. For example, in the figure, the logistics for 12 is needed because only available stock 33 for Period 5 is ready in response to the total requirements 45, and this is set as net requirements.

The procedure to calculate net requirements:

(1) allocatable inventory (t) = released order (t) + available inventory (t - 1)

(2) net requirements (t) = allocatable inventory (t) - total requirements (t)

(3) when the obtained net requirements is a negative number, its absolute figure is used as the net requirements. In contrast, when the obtained net requirements is a positive number, it means the net requirements are all allocated, and thus no net requirements occur and they are handled as available stock.

Related term: Available Stock,Released Order

Reference:JIT Business Research Mr. Hirano Hiroyuki

Calculating Lead Time | Material Planning | Calculating Requirements