MRP glossary TOP > F > Fixed Size Ordering System

Fixed Size Ordering System

Fixed Size Ordering System, Ordering Point System

Related term: Inventory Control Method

It is a representative of statistical inventory control method, and is also called Ordering Point System because an order is issued at the time of reaching the Reorder Point. The method has the following features in the relationship in the demand:

* There are no relationships among the demand of each item, and each demand is independently controlled.

* The demands are continuously made and their seasonal variation is low.

* The issue relatively frequently occurs.

* The percentage of consumption is almost fixed, and the demand fluctuates around the average.

* Slightly many items are stored as inventory.

Thus this method is suitable for independent demand items belonging to B- or C-group, whose demand is stable and price is relatively inexpensive.

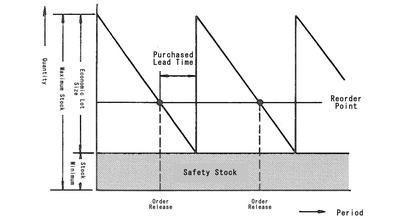

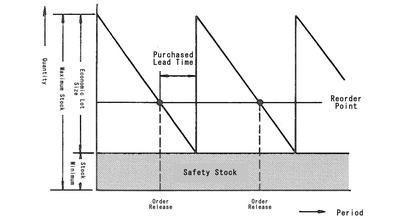

In the Fixed Size Ordering System, the maximum and minimum of standard inventory quantity are defined in advance, and the quantity of inventory gradually decreases, and when the number reaches ROP (Reorder Point, or also just simply OP), an order of EOQ (Economic Order Quantity) is placed.

The ROP is set in the following procedure:

(1) determine the actual consumption of each item

(2) determine EOQ

(3) determine the supplier for each item, and then the purchased lead time

(4) determine safety stock considering demand fluctuations, the variation of delivery date, the lack/loss of stock, and etc.

(5) determine ROP by adding Consumed Amount within Purchased Lead Time to Safety Stock Quantity

Related term: Inventory Control Method

Reference:JIT Business Research Mr. Hirano Hiroyuki