MRP glossary TOP > Material Planning > Order

Order

Order

It is an instruction or logistics to enable products, assemblies, parts, etc. to be identified by item, delivery date, supplier, or person in charge of manufacturing when their items are created or purchased. An order number is usually given to the order as an identification code, and its logistics is made as a manufacturing instruction for manufacturing items, or as a order form for purchasing items.

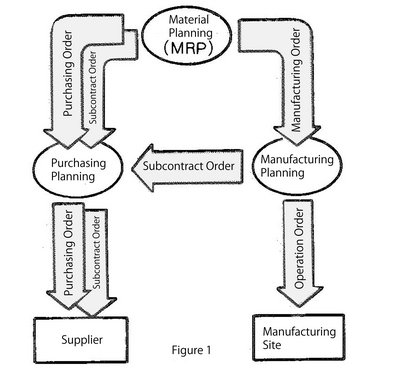

The type of order is classified depending on the logistics of each item, as FIG. 1 shows:

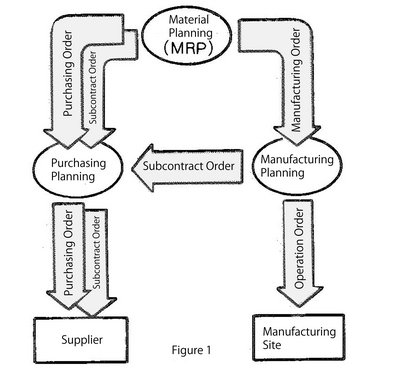

In addition, orders handled are classified as shown in FIG. 2, from the viewpoint of production control's functions.

Related term: Order Status

It is an instruction or logistics to enable products, assemblies, parts, etc. to be identified by item, delivery date, supplier, or person in charge of manufacturing when their items are created or purchased. An order number is usually given to the order as an identification code, and its logistics is made as a manufacturing instruction for manufacturing items, or as a order form for purchasing items.

The type of order is classified depending on the logistics of each item, as FIG. 1 shows:

- Manufacturing Order:

- It is an order necessary for manufacturing items, and it is classified into internal order (to be manufactured by the company itself) and subcontract order (to be manufactured by the subcontractors). The internal order is explored to manufacturing process units, which is called operation orders.

- Purchasing Order:

- It is an order necessary for purchasing items, and its logistics is made with the data relating to suppliers, cost unit, and delivery as well as item, delivery date, and requirements given.

- Subcontract Order:

- It has two types of order: one pre-set in the item unit as subcontract and the other determined as subcontract for capacity reason after the manufacturing planning. The former is usually called Item Subcontract, and the latter is called Process Subcontract. In either case, its logistics is made with not only usual logistics data but also the supplier's data given.

- Operation Order

- It is an order, in which the internal order of manufacturing orders are divided into necessary process unit.

In addition, orders handled are classified as shown in FIG. 2, from the viewpoint of production control's functions.

Related term: Order Status

Reference:JIT Business Research Mr. Hirano Hiroyuki